Let’s work on your project together

Powder Coating Services in Hialeah – Serving All of Miami-Dade

Say Goodbye to Delayed Orders, Embrace Elevated Quality!

Our success is built on the foundation of countless satisfied customers who consistently return to us for all their painting needs.

Guaranteed Quality

Pick up & Delivery available

Custom Color Matching

Rush Service Available

What Can Our Powder Coating & Sandblasting Experts at Fast Paint do for you?

At Fast Paint, we raise powder coating and sandblasting to a new level of excellence. We value your time and adjust to your needs, providing personalized solutions for a variety of markets, including the aerospace, Marine, and industrial sectors. Allow us to transform your expectations into astonishing realities. Your project deserves the quality of Fast Paint.

Real-life results

We generate results for our customers

Here’s how we work our magic:

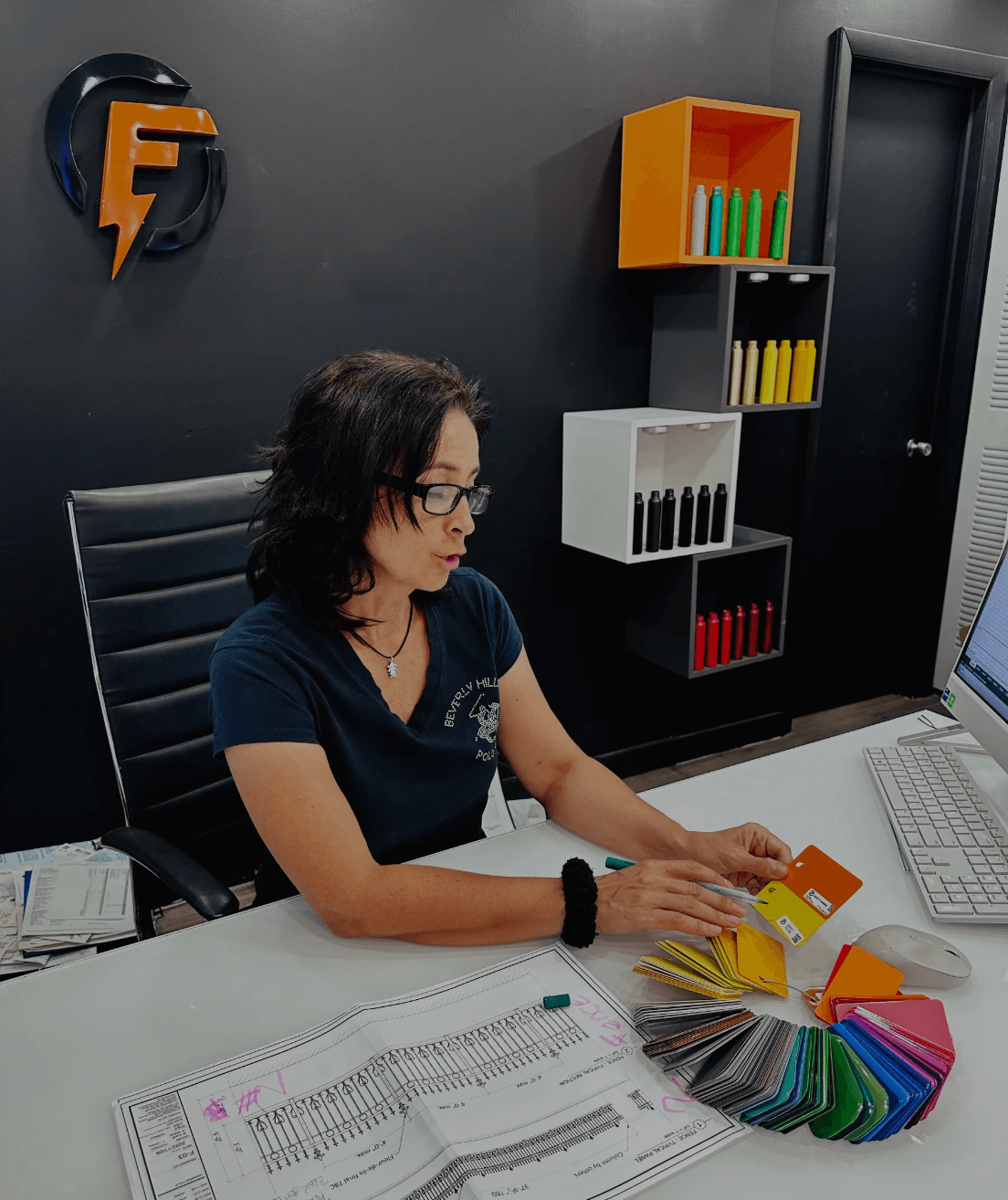

Consultation

We initiate an in-depth conversation with our clients to gain a comprehensive understanding of their distinct needs and goals. This crucial insight empowers us to craft a personalized strategy, meticulously designed to exceed their expectations.

Pretreatment

Our sandblasting & five-stage cleaning system, ensures that every component is meticulously prepared for optimal adhesion and a flawless finish. By removing contaminants and providing a pristine surface, sandblasting helps set the stage for superior results.

Powder Coating Application

Now comes the pivotal stage. In our spray booth, we use advanced guns to electrostatically apply the powder coating. We offer a selection of epoxy for durability, polyester for architectural applications, and polyurethane for flexibility – the perfect coating awaits based on your project’s specific needs.

Curing in a Batch Oven

Lastly, all parts are carefully cured in our batch oven at 430°F for 10-15 minutes. This time may vary according to the material and manufacturer specifications, ensuring each piece gets the ideal finish.

Consultation

We initiate an in-depth conversation with our clients to gain a comprehensive understanding of their distinct needs and goals. This crucial insight empowers us to craft a personalized strategy, meticulously designed to exceed their expectations.

Pretreatment

Our sandblasting & five-stage cleaning system, ensures that every component is meticulously prepared for optimal adhesion and a flawless finish. By removing contaminants and providing a pristine surface, sandblasting helps set the stage for superior results.

Powder Coating Application

Now comes the pivotal stage. In our spray booth, we use advanced guns to electrostatically apply the powder coating. We offer a selection of epoxy for durability, polyester for architectural applications, and polyurethane for flexibility – the perfect coating awaits based on your project’s specific needs.

Curing in a Batch Oven

Lastly, all parts are carefully cured in our batch oven at 430°F for 10-15 minutes. This time may vary according to the material and manufacturer specifications, ensuring each piece gets the ideal finish.

Protection and Transportation

After the piece has been successfully coated and cured, it is crucial to ensure its integrity during storage and transportation. To do this, the powder-coated piece is carefully wrapped in protective material to avoid any scratches or damage that could affect its final finish.

Let’s work together