High-Quality Aerospace Powder Coating and Sandblasting Services

As a player in the aeronautic industry, you know that quality and reliability are crucial. That’s why we’re proud to offer our exceptional aerospace powder coating and sandblasting services, designed to meet the unique demands of the aeronautic market, right here in Miami. No job is too big for our team – we specialize in handling heavy jobs and large parts!

Guaranteed Quality

Pick up & Delivery available

Custom Color Matching

Rush Service Available

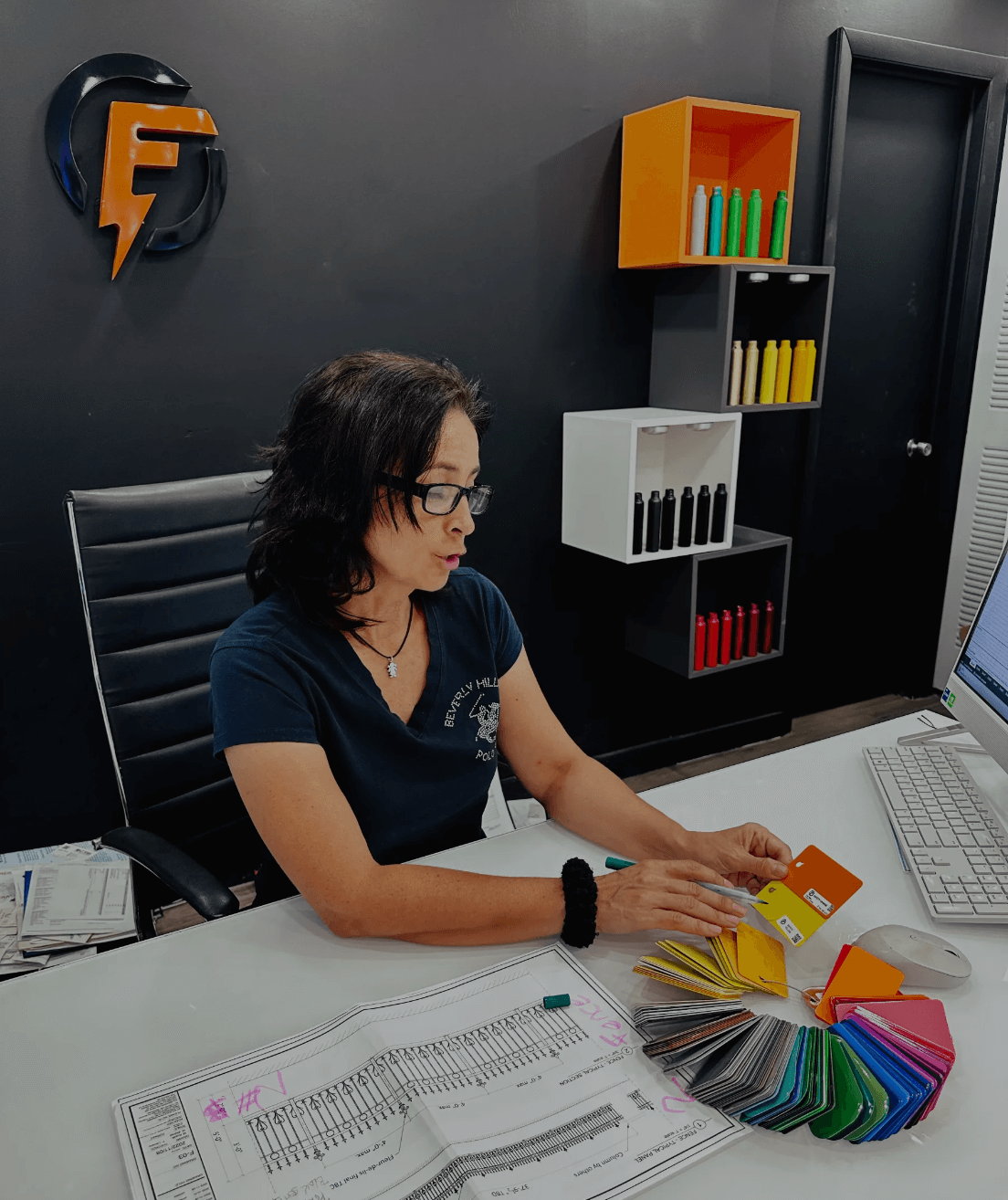

Real-life results

We generate results for our customers

Elevating Aerospace Standards with Precision Coating

The aerospace sector demands unparalleled reliability, precision, and durability. At Fast Paint Miami, we deliver specialized powder coating and sandblasting services tailored to the rigorous standards of the aerospace industry. Our coatings offer exceptional resistance to extreme temperatures, corrosion, and environmental wear, ensuring your components meet and exceed performance expectations. From turbine blades to structural panels, we provide flawless finishes that support optimal functionality and extend the lifespan of your aerospace equipment.

Precision Aerospace Powder Coating Services in Miami, FL

In the aerospace industry, precision and performance are essential, which is why Fast Paint Miami is proud to offer specialized aerospace powder coating solutions. Our services are tailored to meet the stringent requirements of aeronautic components, providing superior protection from extreme temperatures, moisture, and wear. We excel in handling large parts and complex geometries, ensuring consistent, high-quality coatings that enhance the performance and longevity of aircraft components. With a commitment to guaranteed quality and custom color matching, our powder coating process ensures that your aerospace equipment is both aesthetically pleasing and highly functional. No matter the scope of your project, we’re ready to tackle even the most demanding jobs with precision and expertise.

Here’s how we work our magic:

Consultation

We initiate an in-depth conversation with our clients to gain a comprehensive understanding of their distinct needs and goals. This crucial insight empowers us to craft a personalized strategy, meticulously designed to exceed their expectations.

Pretreatment

Our sandblasting & five-stage cleaning system, ensures that every component is meticulously prepared for optimal adhesion and a flawless finish. By removing contaminants and providing a pristine surface, sandblasting helps set the stage for superior results.

Powder Coating Application

Now comes the pivotal stage. In our spray booth, we use advanced guns to electrostatically apply the powder coating. We offer a selection of epoxy for durability, polyester for architectural applications, and polyurethane for flexibility – the perfect coating awaits based on your project’s specific needs.

Curing in a Batch Oven

Lastly, all parts are carefully cured in our batch oven at 430°F for 10-15 minutes. This time may vary according to the material and manufacturer specifications, ensuring each piece gets the ideal finish.

Consultation

We initiate an in-depth conversation with our clients to gain a comprehensive understanding of their distinct needs and goals. This crucial insight empowers us to craft a personalized strategy, meticulously designed to exceed their expectations.

Pretreatment

Our sandblasting & five-stage cleaning system, ensures that every component is meticulously prepared for optimal adhesion and a flawless finish. By removing contaminants and providing a pristine surface, sandblasting helps set the stage for superior results.

Powder Coating Application

Now comes the pivotal stage. In our spray booth, we use advanced guns to electrostatically apply the powder coating. We offer a selection of epoxy for durability, polyester for architectural applications, and polyurethane for flexibility – the perfect coating awaits based on your project’s specific needs.

Curing in a Batch Oven

Lastly, all parts are carefully cured in our batch oven at 430°F for 10-15 minutes. This time may vary according to the material and manufacturer specifications, ensuring each piece gets the ideal finish.

Protection and Transportation

After the piece has been successfully coated and cured, it is crucial to ensure its integrity during storage and transportation. To do this, the powder-coated piece is carefully wrapped in protective material to avoid any scratches or damage that could affect its final finish.

Let’s work together

We produce results for our customers

Trust Our Aerospace Powder Coating Services in Miami, FL for Superior Durability and Expert Finishes

Fast Paint Miami provides aerospace powder coating services in Miami, FL for clients who demand excellence. Our coatings resist extreme temperatures, moisture, and corrosion, helping aircraft components withstand intense operating environments while maintaining structural integrity. With pickup and delivery, rush options, and the capability to handle large, heavy parts, we ensure efficient service and remarkable results. Contact us today to get started and enjoy 10% off your first aerospace project.

Our services