Our Expert Sandblasting Services

The best industrial finishes in the country!

Precision and Care

Our sandblasting technique ensures maximum efficacy without damaging the underlying material.

Revitalization

Bring new life to old, worn-out surfaces, making them look brand new again.

Versatility

Perfect for a variety of materials, including metal, wood, glass, and more.

Time Efficiency

Our advanced technology and experienced team mean quick turnaround times, minimizing any disruption to your daily life or business operations.

Applications of Sandblasting and Powder Coating

Our services are versatile and adaptable to a wide range of industries and materials.

Marine Applications: Protect and enhance your boat’s components, including T-tops, hulls, and railings, with durable finishes that withstand harsh marine environments.

Industrial Solutions: From heavy machinery to structural components, our sandblasting and powder coating services restore functionality and improve longevity in demanding industrial settings.

Outdoor Furniture: Revitalize metal or wooden outdoor furniture with a sleek, weather-resistant finish, ensuring it looks great and lasts for years to come.

Aerospace Enhancements: Our precision sandblasting and powder coating services meet the stringent requirements of the aerospace industry, delivering quality finishes for aircraft components.

Real-life results

We generate results for our customers

Why Choose Fast Paint Miami?

At Fast Paint Miami, we pride ourselves on delivering top-tier sandblasting and powder coating services tailored to meet the unique needs of our clients. With over 20 years of experience, we have the expertise, equipment, and dedication to ensure exceptional results every time.

Here’s what sets us apart:

State-of-the-Art Equipment: From advanced sandblasting machines to a 30-ft cure oven, we use cutting-edge tools to achieve precision and efficiency.

Experienced Team: Our professionals bring unmatched skill and attention to detail to every project.

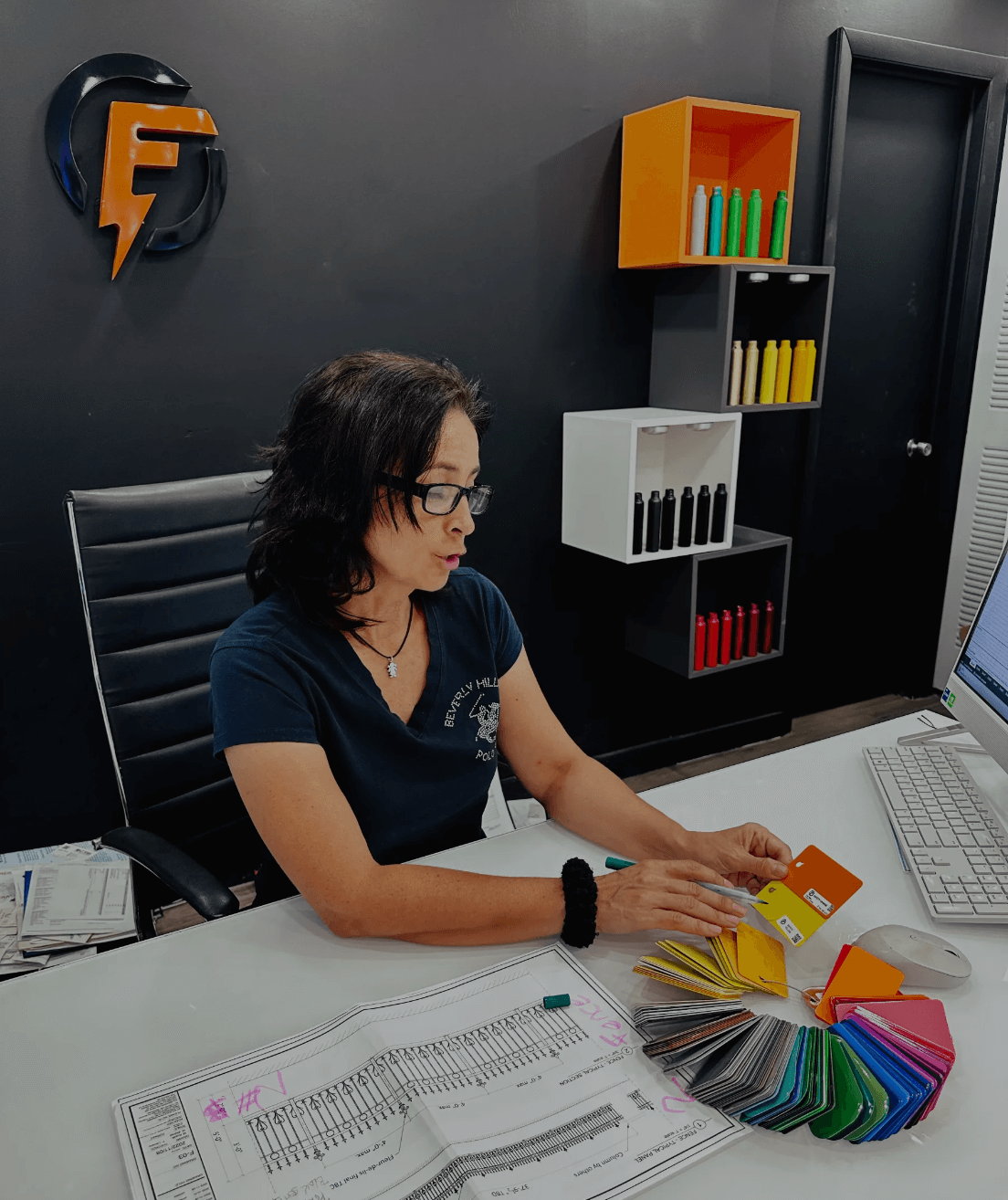

Customer-Centric Approach: We prioritize your vision, ensuring that every job aligns with your goals and expectations.

The Benefits of Sandblasting for Surface Preparation

Sandblasting is one of the most effective methods for preparing surfaces before applying coatings or paint. By removing rust, old paint, and other contaminants, it creates a clean and textured surface that enhances adhesion and ensures a smooth, long-lasting finish. This process is ideal for restoring metal, wood, and even concrete surfaces, making them look brand new and ready for their next treatment. Whether you’re refinishing outdoor furniture, industrial equipment, or marine components, proper surface preparation through sandblasting leads to superior results and extended durability.

Get a Free Quote Today

If you need professional sandblasting or powder coating services, we’re here to help. Our expert team works with a variety of materials and industries, providing high-quality results tailored to your needs. Contact us today to discuss your project and get a free quote. Let us bring new life to your surfaces with precision and care.

Here’s how we work our magic:

Consultation

We initiate an in-depth conversation with our clients to gain a comprehensive understanding of their distinct needs and goals. This crucial insight empowers us to craft a personalized strategy, meticulously designed to exceed their expectations.

Pretreatment

Our sandblasting & five-stage cleaning system, ensures that every component is meticulously prepared for optimal adhesion and a flawless finish. By removing contaminants and providing a pristine surface, sandblasting helps set the stage for superior results.

Powder Coating Application

Now comes the pivotal stage. In our spray booth, we use advanced guns to electrostatically apply the powder coating. We offer a selection of epoxy for durability, polyester for architectural applications, and polyurethane for flexibility – the perfect coating awaits based on your project’s specific needs.

Curing in a Batch Oven

Lastly, all parts are carefully cured in our batch oven at 430°F for 10-15 minutes. This time may vary according to the material and manufacturer specifications, ensuring each piece gets the ideal finish.

Consultation

We initiate an in-depth conversation with our clients to gain a comprehensive understanding of their distinct needs and goals. This crucial insight empowers us to craft a personalized strategy, meticulously designed to exceed their expectations.

Pretreatment

Our sandblasting & five-stage cleaning system, ensures that every component is meticulously prepared for optimal adhesion and a flawless finish. By removing contaminants and providing a pristine surface, sandblasting helps set the stage for superior results.

Powder Coating Application

Now comes the pivotal stage. In our spray booth, we use advanced guns to electrostatically apply the powder coating. We offer a selection of epoxy for durability, polyester for architectural applications, and polyurethane for flexibility – the perfect coating awaits based on your project’s specific needs.

Curing in a Batch Oven

Lastly, all parts are carefully cured in our batch oven at 430°F for 10-15 minutes. This time may vary according to the material and manufacturer specifications, ensuring each piece gets the ideal finish.

Protection and Transportation

After the piece has been successfully coated and cured, it is crucial to ensure its integrity during storage and transportation. To do this, the powder-coated piece is carefully wrapped in protective material to avoid any scratches or damage that could affect its final finish.

Let’s work together